ANDRITZ PULP & PAPER is a global market leader in the supply of systems and services from the woodyard to paper finishing. The ANDRITZ tissue technology group offers customized dry-crepe, textured, and structured (TAD), as well as standardized tissue machine concepts. Air and energy solutions as well as comprehensive services complement the portfolio. The tissue machines are equipped with a PrimeDry Steel Yankee, and can also be equipped with a PrimePress XT Evo shoe press, heat recovery re-evaporation systems and steam-heated hoods which all help to achieve remarkable resource savings. ANDRITZ PULP & PAPER is also a leading global supplier of fiber preparation systems and equipment for fiber, sludge, reject and internal water loop handling. Service activities are focused on assisting customers to increase their operational efficiency while reducing operating costs.

Areas of competence, expertise and contributions in tissue:

- World’s most modern tissue pilot plant (PrimeLineTIAC) to conduct trials and to create future technologies

- Complete lines from stock preparation to the reel including fabrics and rolls, automation/digitalization, and pumps

- Turn-key solutions for tissue production

- Tissue machines for the production of dry-crepe, textured, and structured (TAD) tissue

- Rebuilds and key components for energy savings and production efficiency

- Steel Yankees including head insulation, and services likes grinding, coating, and On-The-Run measurements

- Air and energy systems

- Comprehensive service activities to keep maintenance costs low and product lifetime at a maximum

Website link:

www.andritz.com/tissuemachines

Primary contact:

Elisabeth Wolfond

Marketing Director

Paper, Fiber, and Recycling

elisabeth.wolfond@andritz.com

PrimeLineTM W8: CrescentFormer tissue machine with energy and resource saving components.

The world’s most modern tissue pilot plant: PrimeLineTIAC – Tissue Innovation and Application Center.

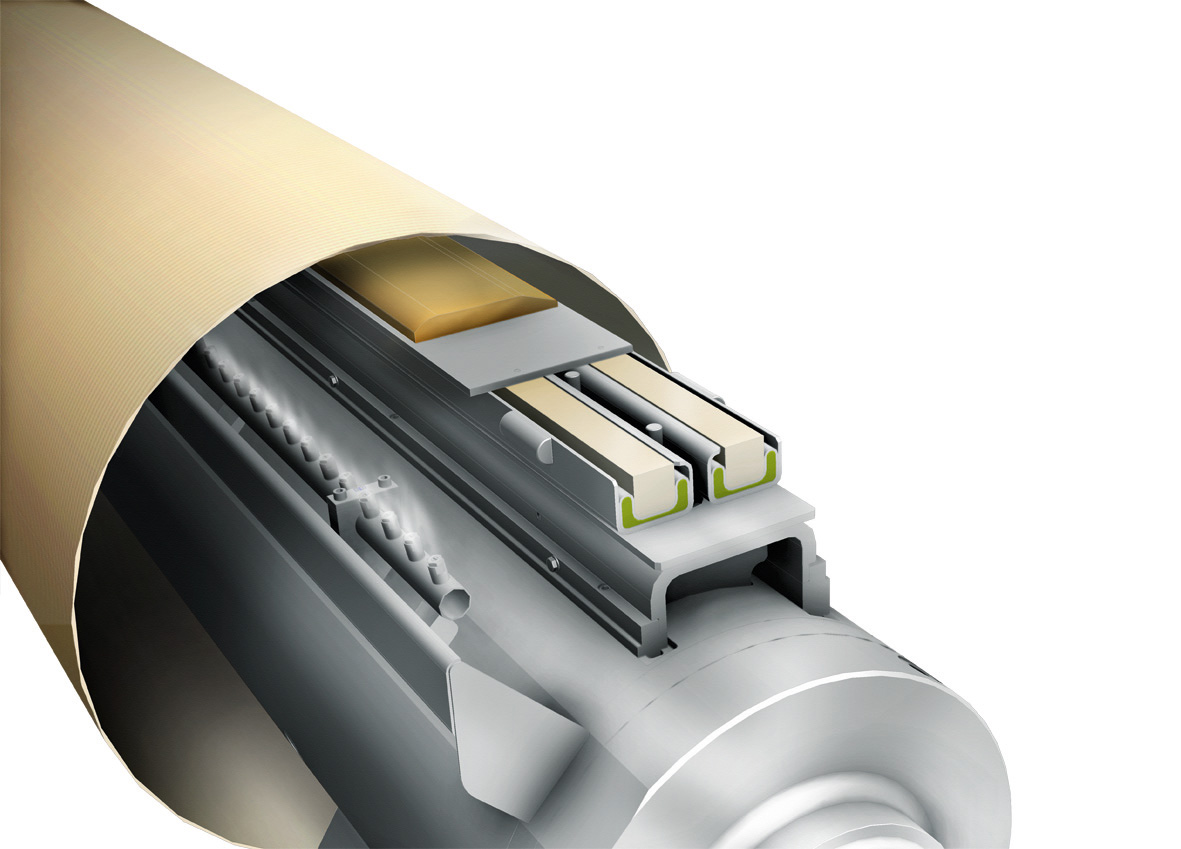

PrimePress XT Evo: the new generation of shoe presses for improved dewatering, higher post-press dryness, and reduced need for thermal drying.