.. Staying Ahead in Today’s Rapidly Shifting Retail Landscape As Senior Buyer for one of the world’s largest supermarket chains, Patrick Boateng runs at a very fast pace. At Kroger... read more →

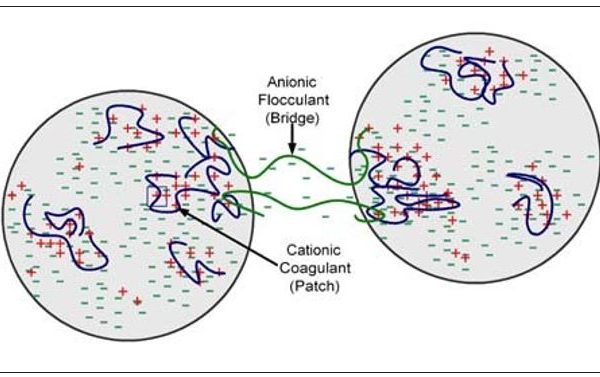

... Retention aids have long been used in graphic and packaging grades of paper and board. Their benefits in terms of production and raw material efficiencies are well known. However,... read more →

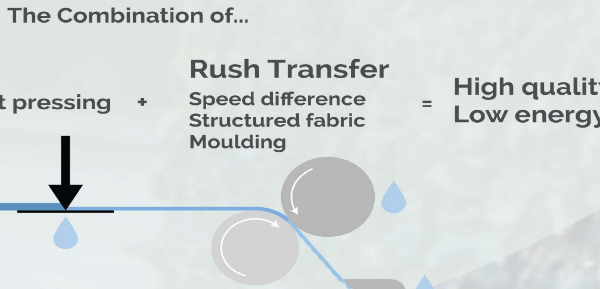

.. A series of recent machine developments mean tissue makers now have a wider range of options than ever before when considering what kind of structured tissue to make “Any... read more →

... Retention aids are commonly used in tissue manufacturing to retain fines and get improvements in machine efficiency and costs of operation. And, although tissue makers generally know that wet-end... read more →

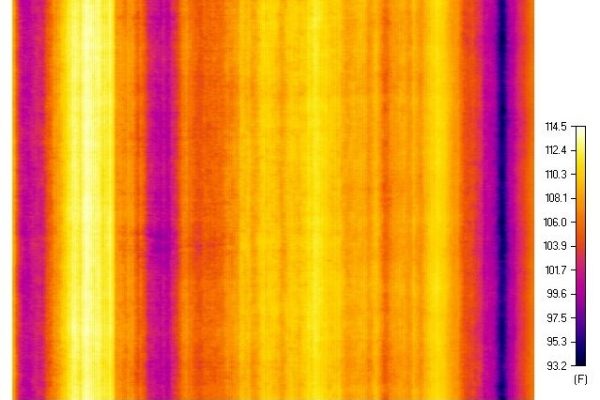

.. Drying is sometimes said to be the 'least understood' process in papermaking. New tools can help solve old problems, giving tissue makers substantial energy, cost and emissions savings. Take... read more →

-- Consistent growth over the past 30 years has led the tissue sector to become the single-biggest consumer of market pulp, claiming an estimated 36% of global bleached chemical pulp... read more →

Scientific studies prove his concerns about bacteria and virus contamination are justified. Worry about negative health effects caused by bacteria and viruses that may be widely spread by air... read more →

.. By taking a broad view, combined with detailed process knowledge and modern tools, troublesome Yankee problems can usually be solved quite rapidly By Erwin Walcher and Wolfgang Herbst, Andritz... read more →

.. If, as is often stated, the Yankee dryer is the Heart of a tissue machine, then the steam and condensate (S&C) systems can certainly be referred to as its... read more →

... By Keith Meyer and Richard Turnbull, Andritz 1. Introduction There are a variety of ways to produce tissue and towel products from wood-based fiber furnishes. These may include the... read more →