To get our occasional e-mail Summary, which can be unsubscribed at any time, please leave your email address here

Tissue Making Involves Advanced Science

An important aspect of tissue paper products that is sometimes overlooked is the advanced science and technology used to make them. Tissue products are not simple commodities, but instead are high-tech paper specialties based on complex science. To make a tissue sheet, weighing sometimes as little as 13 grams per square meter, with softness, strength and absorbency engineered into the products, is no simple task.

To learn more about the science and technology of tissue making, continue browsing down this page

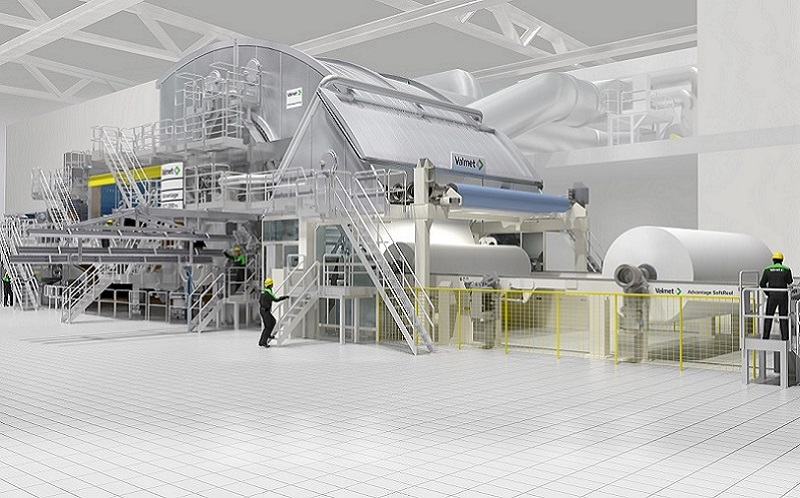

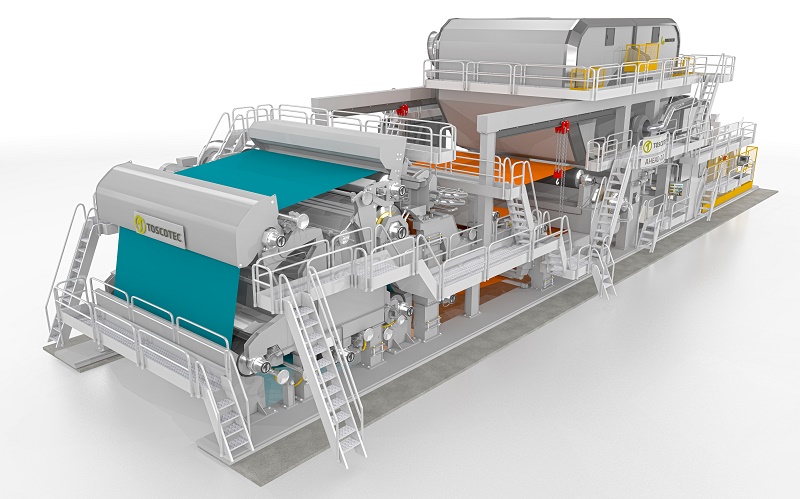

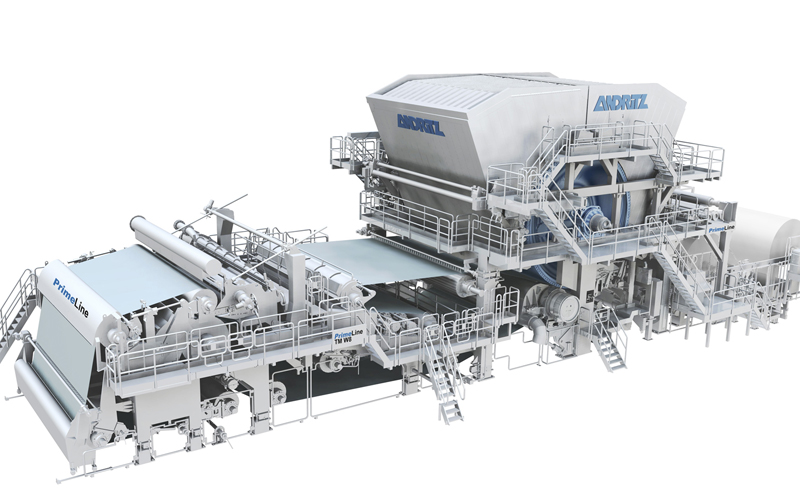

Paper Engineering with Giant Machines

It has been stated, although it may be hard to confirm, that a modern paper machine has as much advanced technology as a jet airliner. Tissue machines making the ultra-light tissue paper can be as wide as 8 m (26 feet) across and running as fast as 2,000 meters per minute (75 mph). Many factors must be combined to achieve this. This field is called Paper Engineering, which deals with physical sciences like chemistry, physics, and mechanical engineering, combined with life sciences such as biology and biochemistry in conjunction with mathematics and applied to convert raw materials into these useful paper products.

Ultra-Light Sheet provides Important Functional Properties

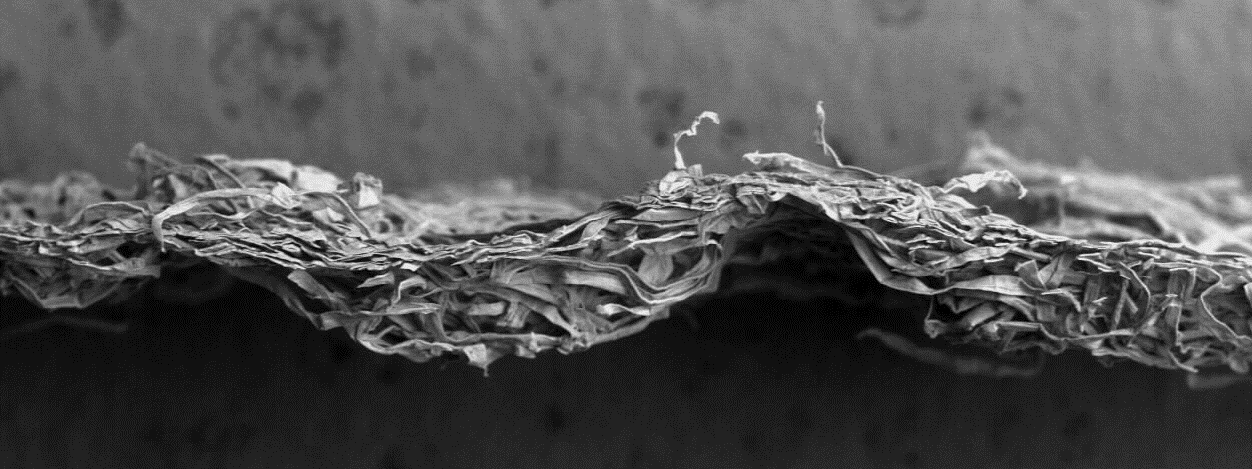

Highly-magnified (100x approx.) cross section of structured tissue sheet

Paper in general, and tissue specifically, is a remarkably versatile and multi-functional web or sheet based on the non-directional entanglement and bonding of fibers, primarily wood fibers. For tissue products, numerous desired functional properties can be built in to the sheet depending on the end use. These include softness, strength, absorbency, biodegradability, and other necessary functionality.

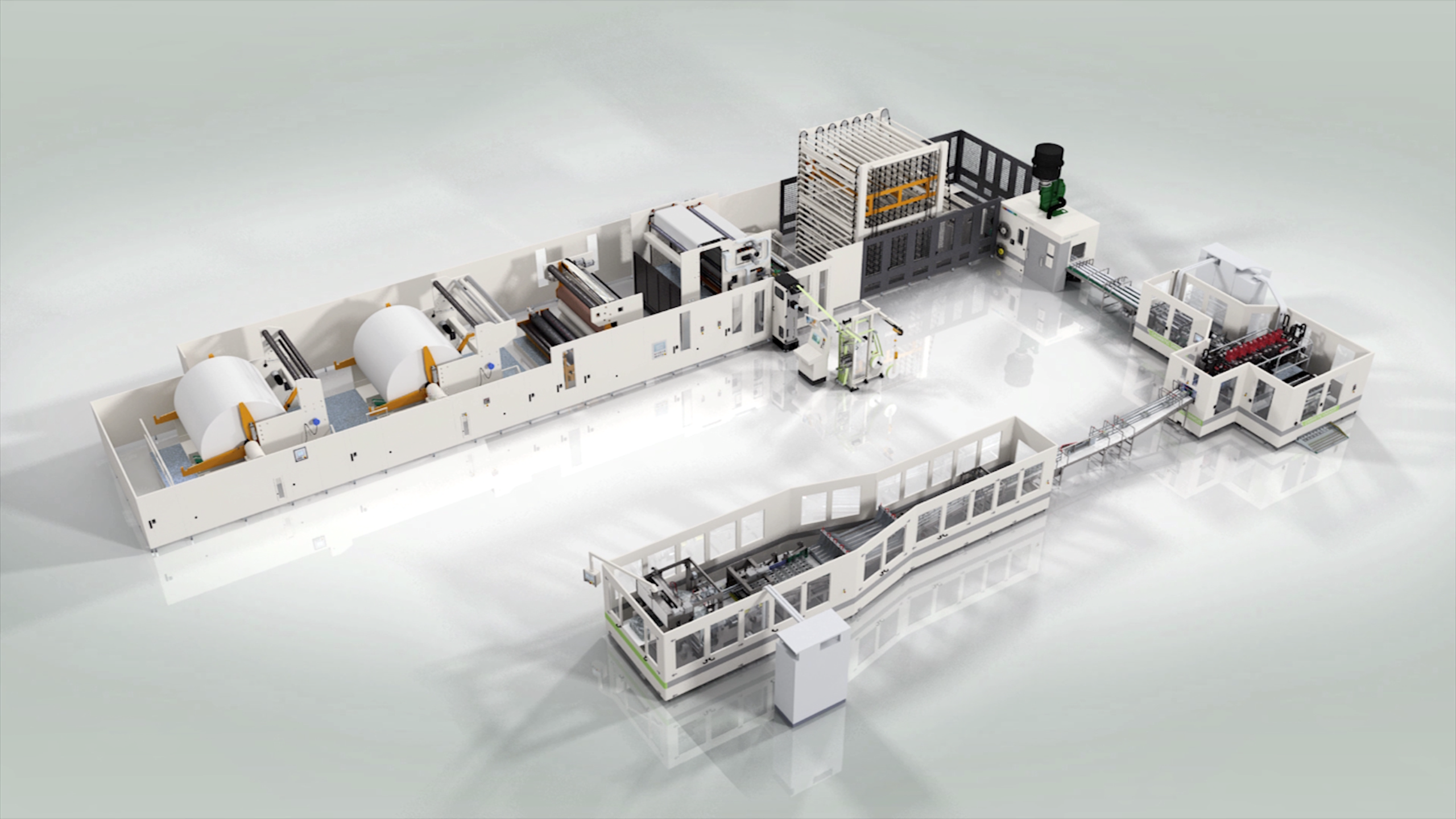

Converting and Packaging

Tissue is made on the paper machine in large jumbo rolls which can weigh up to several tons. These are then transformed in the converting process from very large reels into finished products such as rolls of bathroom tissue or kitchen paper towels, as well as folded products like facial tissue, handkerchiefs and napkins. Advanced high-speed machines carry out the complex winding, cutting, slitting, printing and embossing steps while retaining the functional properties such as softness, strength and absorbency. Finally, these products are wrapped and packaged into the format needed for stocking in a supermarket or other distribution center before going to the final consumer.

Fiber Chemistry & Physics Is a Science in Itself

Cellulosic wood fibers which make up the paper sheet

Tissue is made of wood fibers, which are the small hair-like strands that you can see if you rip a piece of tissue and look at the edges. Wood fibers are actually quite advanced biopolymers and scientists have spent lifetimes studying the chemistry and physics of these remarkable structures. Using high-tech engineering and advanced chemistry, the properties of the fibers can be customized to get the optimal performance of the tissue sheet.

There Is an Large Amount of Science and Engineering That Goes into Tissue Making.

Please feel free to share this content. Click on your favorite social media below. Thank you!